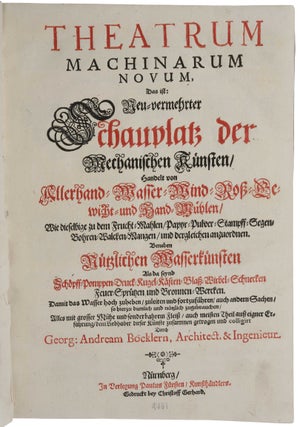

Theatrum Machinarum Novum. Das ist: Neu-vermehrter Schauplatz der Mechanischen Künsten: Handelt von allerhand Wasser- Wind- Roß- Gewicht- und Hand-Mühlen, Wie dieselbige zu dem Frucht-Mahlen, Papyr- Pulver- Stampff- Segen- Bohren- Walcken- Mangen, und dergleichen anzuordnen; Beneben Nützlichen Wasser-Künsten Als da seynd Schöpff- Pomppen- Druck- Kugel- Kästen- Blaß- Wirbel- Schnecken Feuer-Sprützen und Bronnen-Wercken. Damit das Wasser hoch zu heben, zu leiten und fortzuführen, auch andern Sachen, so hierzu dienlich und nützlich zugebrauchen …

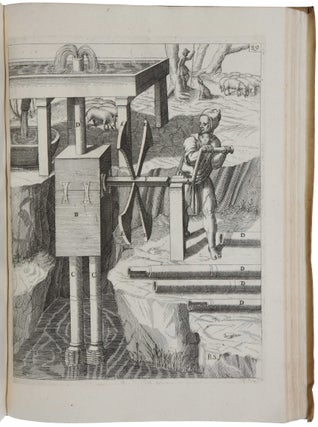

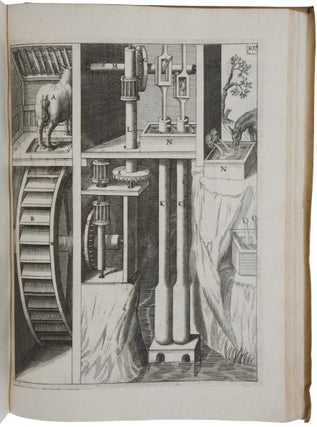

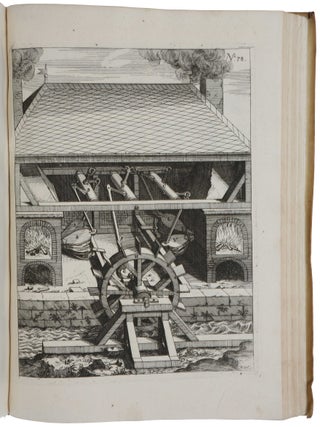

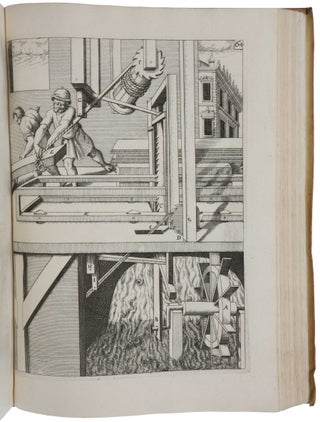

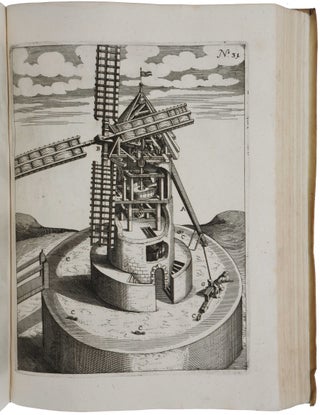

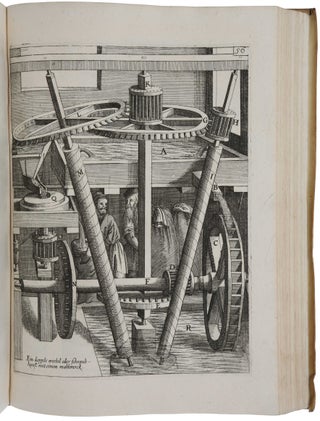

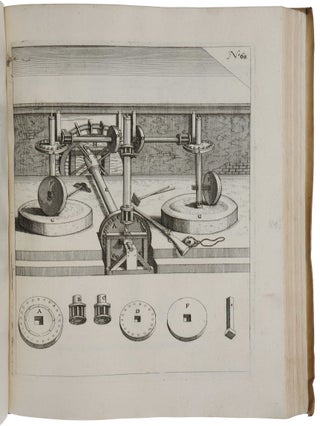

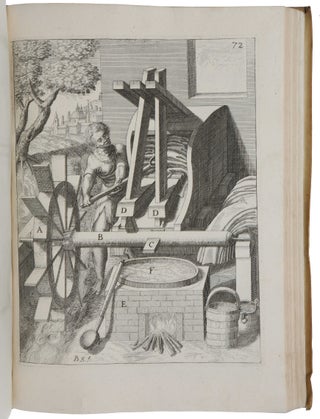

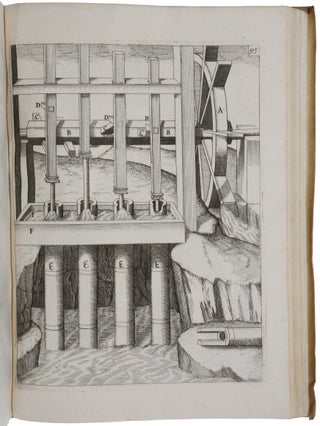

Nuremberg: Christoff Gerhard for Paul Fürst, 1661. First edition, an exceptionally fine copy in an untouched contemporary binding, of this superbly illustrated work with 154 plates of various types of powered mills and hydraulic machinery. “Here is another of the great ‘machine’ books with many beautiful engravings of gunpowder mills, saw mills, water raising devices, fire engines, roasting spits and so on. Böckler was a German architect and engineer interested in masses of gearing, complex workings, and devices that even by modern standards invite awe and admiration” (Hoover). The magnificent plates are of various types of motion drives powered by intricate systems of wheels employing water, wind, weights, horse power, human muscle, or some striking combinations of these. Plates 73 and 74 depict paper-making equipment and processes, which are “the clearest delineation of the art to this date” (Hunter, The Literature of Papermaking, page 18): they show the linen rags being pulped with water-powered hammers, while the vatman stands ready with a mould, the coucher presses the post, and the drying sheets hang on ropes above, ready to be sized, calendared, gathered into reams, and packaged. Plate 5 pictures a hand mill for making ink for copperplate printing. The last plate (no. 154) is extraordinary for its depiction of a fire engine water pump made by the Nuremberg inventor Hans Hautsch in 1658. The suction-and-force mechanism of Hautsch’s clever device (described on pp. 60-1 of Böckler’s text) enabled twenty-four men to raise water to a height of eighty to one hundred feet in a continuous stream. Current historians of engineering view it as the basis of the modern fire engine. Among the other ingenious machines is a famous attempt at designing a perpetual motion machine (p. 59). However, Jakob (pp. 124-5) emphasizes that Böckler’s work is at a higher technical level, and has far fewer ‘miraculous machines’ than other Baroque machine books, such as those of Agostino Ramelli and Salomon de Caus. Many of the engravings are familiar because they were plagiarized in technology publications for the next hundred years. Although the book appears with some regularity on the market, copies in such fine condition as ours are notably rare. “It was in Germany that two of the most eminent engineering visionaries lived. The first of these was Georg Andreas Böckler who published a truly remarkable book … called Theatrum Machinarum Novum, written and illustrated as a record of the progress of the art of engineering. “As one might gather, not just from the title page but from a knowledge of the general conditions pertaining in Germany after the Thirty Years’ War, Böckler’s acquaintance with machinery was restricted almost entirely to mills of one sort or another. In most of these, regardless of the motive power, he depicts the precursor of the geared transmission familiar to this day. “The seventeenth-century engineers had neither the theoretical knowledge nor the technical equipment to design and shape gear-wheels which would mesh with minimum friction. In fact, friction as such, although made use of in such applications as the sack-lift in a mill, was little understood. The construction of pinions to mesh with larger gear-wheels had yet to assume the form common today. However, the problem of shifting the direction of rotation of a drive through 90° was solved by the invention of the wallower driven either by a contrite wheel (a wooden wheel with tooth pegs protruding around the circumference parallel to the axis) or by a cogwheel having teeth projecting radially around the circumference at right-angles to the axis … The wallower comprised two discs of wood, each drilled with a matching set of concentric holes near the perimeter. The discs, usually with square centre bores to aid fixing and to transmit rotary motion, were mounted on a shaft separate by a gap of as much as the mechanism dictated, and threaded through the holes, from one disc to the next, were wooden rods. The result looked not unlike a birdcage or lantern, hence its more common name. When it was meshed with a large wheel having suitably spaced wooden pegs around either its diameter (the contrite) or its periphery (the cog), depending on whether parallel or perpendicular motion was desired, a serviceable gear train was the result. Friction, though cut efficiency drastically. All this is depicted in Böckler’s Theatre of New Machines” (Ord-Hume, Perpetual Motion (2015), pp. 47-8). Among the many other remarkable mills illustrated in Böckler’s Theatre, we mention Plate 72, which shows a ‘fulling mill’. Fulling is a step in fabric production that involves pounding cloths to clean them. In the illustration, tappets, C, on the shaft, B, raise and lower mallets, D, which pound the woollen cloth. Other mills are used for grinding flour (Plates 37, 41, 46, 47, 59), for sharpening stones (Plate 34), and for sharpening tools and knives (Plate 36). “The continuous rotary motion produced by the vertical water wheel was applied to both working wood and rolling and cutting metals during the medieval period, as well as to milling and grinding … The rotary motion of the water wheel may also have been used in the medieval period for other tasks. There is evidence … of water-powered chain-of-bucket or rag-and-chain pumps for draining mines” (Reynolds, Stronger Than a Hundred Men: A History of the Vertical Water Wheel (2002), pp. 76-8). This last application is illustrated on Plate 116. “Probably the most widely applied water-powered innovation in the food processing industry in this period was the mechanical bolter, used in flour mills to automatically sift flour. The bolter was basically a sheet or roll of wire mesh or cloth (most often canvas or linen, but sometimes silk or another fabric). The flour produced by the mill was fed through or over the device, which was shaken by a mechanism (several were possible) taking power from the drive train leading from the water to the millstones … The bolter depicted by Böckler [on Plate 45] indicates just how simple the device could sometimes be” (ibid, p. 138). Other devices powered by water wheels are an irrigation pump (Plates 35, 95, 98, 109, 110), a forge (Plate 79) with bellows and hammer powered by an undershot water wheel, and a corn mill (Plates 45, 46, 47). The key breakthrough in fire-fighting arrived in the seventeenth century with the first fire engines. Manual pumps, rediscovered in Europe after 1500, were only force pumps and had a very short range due to the lack of hoses. Hans Hautsch (1595-1670) improved the manual pump by creating the first suction and force pump and adding some flexible hoses to the pump. His fire-engine consisted of a water cistern about 8 feet long, 4 feet high, and 2 feet in width, and was drawn on a kind of sledge somewhat larger than the cistern. It was worked by 28 men, and a stream of water an inch in diameter was forced, by means of this engine, to an elevation of nearly 80 feet. This remarkable machine is illustrated on Plate 154. A recurring theme in the book is the perpetual motion machine. “The use of water-power seems particularly prone to implant the idea in the human mind. This is probably attributable to the assumption that water comes from nowhere in particular and costs Man nothing. This deludes the miller into assuming that his power costs him nothing by concealing the fact that his power is bought and paid for in terms of units of energy and that it can be delivered to him but once. In any event, it would seem that the proprietor of a water-mill – especially of one whose driving stream was subject to seasonal diminutions of flow – was forever trying to make his water run back uphill and work for him again. Later and wiser mill engineers accumulated their energy when it was plentiful by constructing mill-ponds with sluice gates so that when the natural water flow was diminished, reserves could be drawn upon which did not defy the laws of Nature. “Unfortunately for the peace of the medieval mind, it knew of at least one highly plausible scheme for making water run uphill. If the end of a pipe, coiled like the thread of a screw, is immersed in water, and the whole pipe rotated like a screw, the water will climb up the pipe and keep on climbing so long as the pipe is kept turning. This strange but perfectly workable invention is called an Archimedean screw … What we know and understand about the Archimedean screw is that the pipe must be turned by some outside agency. This illuminating piece of information was not understood by our ancestors who, with glinting eyes, asked ‘What could be more simple than to connect such an Archimedean screw with the water-wheel of a mill, and make the mill run the screw, and the screw run the mill?’ To Böckler, as to so many others both before and after his time, the answer was that nothing indeed was more simple. Böckler’s mills, which he illustrated in plenitude, all worked on this principle … One notable feature of the Archimedean perpetual motion machine depicted here is the shape of the motive blades which bear a strong resemblance to the modern turbine” (Ord-Hume, pp. 48-50). This Archimedean screw arrangement is beautifully illustrated on Plate 54, which shows an overshot water wheel that powers a grindstone and an Archimedes screw that returns the water to the reservoir driving the wheel. “Another means for making a mill raise the water for its own power which Böckler used in several instances consisted of a series of cups attached to an endless rope. The cups were expected to re-deliver the water direct to the wheel. But it was the self-moving wheel that appeared the most plausible. Here, with an apparent permanent preponderance of weights on one side of the wheel, once motion was started it seemed obvious that the wheel would not only rotate continuously but would generate enough power to pump water” (ibid., p. 50). This perpetual motion machine is illustrated on Plate 130: the water wheel, C, through the gearing network D, E, F G, H, I, drove a chain-of-buckets pump K which lifted water to reservoir A, from which the water wheel derived its power. As Knoespel points out (p. 110), a comparison of Böckler’ work with earlier machine books indicates the transformation then underway in the status of human beings relative to that of machines, “for the focal point within the illustrations has shifted from the human to the mechanical … Böckler shows a more developed awareness of how machines alter the status of workers was well as owners in his seventeenth-century illustrations. In one, a curtain has been drawn aside to reveal a couple at leisure eating dinner while the mill, tended by workers, operates on the floor beneath them (plate 53). Here the machine begins to determine the roles played by humans. The various illustrations portraying humans attentively watching a machine’s operation indicate even further the centrality of the apparatus in the drama being portrayed.” Born in Cronheim ca. 1617, Böckler was an architect in Nuremberg. In addition to the present work he is the author of Architectura Curiosa Nova (Nuremberg, 1664), which dealt with the theory and application of hydrodynamics for water-jets, fountains and well heads with many designs for free-standing fountains. Böckler died in Ansbach in 1667. Böckler’s Theatre proved extremely popular, with later German editions appearing in 1673, 1703 and 1705, and Latin translations in 1662 and 1686. Graesse I, 459; Stanitz 46; Zachert/Zeidler I, 220; [for the 1662 Latin edition see:] Macclesfield 2195; Horblit 132; Honeyman 359. Singer, History of Technology III.16-17. Hoover, Bibliotheca De re Metallica, 142 (for the 1686 Latin edition). Jakob, Maschine. Mentales Modell und Metapher. Studien zur Semantik und Geschichte der Techniksprache, 1991; Knoespel, ‘Gazing on Technology: Theatrum Mechanorum and the Assimilation of Renaissance Machinery,’ Literature and Technology (Greenberg & Schachterle, eds.), 1992, pp. 99-124.

Folio (312 x 223 mm), pp. [xii], 68, including engraved title, and letterpress title printed in red and black, ornamental initials and head and tailpieces, with 154 engraved plates. Contemporary vellum with yapped edges.

Item #4491

Price: $18,500.00